| 美國UNS | C42500 |

|---|---|

| 對應标準 | ASTM B591-2015

銅-鎳-鋅以及銅-鎳-鋅-鐵-鎳合金厚闆, 薄闆, 帶材和軋制棒材的标準規範 Copper-Zinc-Tin and Copper-Zinc-Tin-Iron-Nickel Alloys Plate, Sheet, Strip, and Rolled Bar |

| 歸類 | 銅及銅合金 |

-

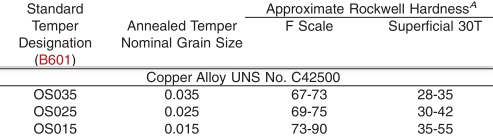

退火材料的近似洛氏硬度

Rockwell hardness values apply as follows: The F scale applies to metal 0.020 in. (0.5 mm) in thickness and over; the 30T scale applies to metal 0.015 in. (0.38 mm) in thickness and over.

注:數據僅供參考!如有疑問,請填寫"我要糾錯"!